Galvanized wire is processed from high-quality low-carbon steel wire rods, going through technological processes such as wire drawing forming, pickling for rust removal, high-temperature annealing, hot-dip galvanization, and cooling. Galvanized wire is divided into two types: hot-dip galvanized wire and cold-dip galvanized wire (also known as electro-galvanized wire). Their differences are as follows:

Hot-Dip Galvanized Wire

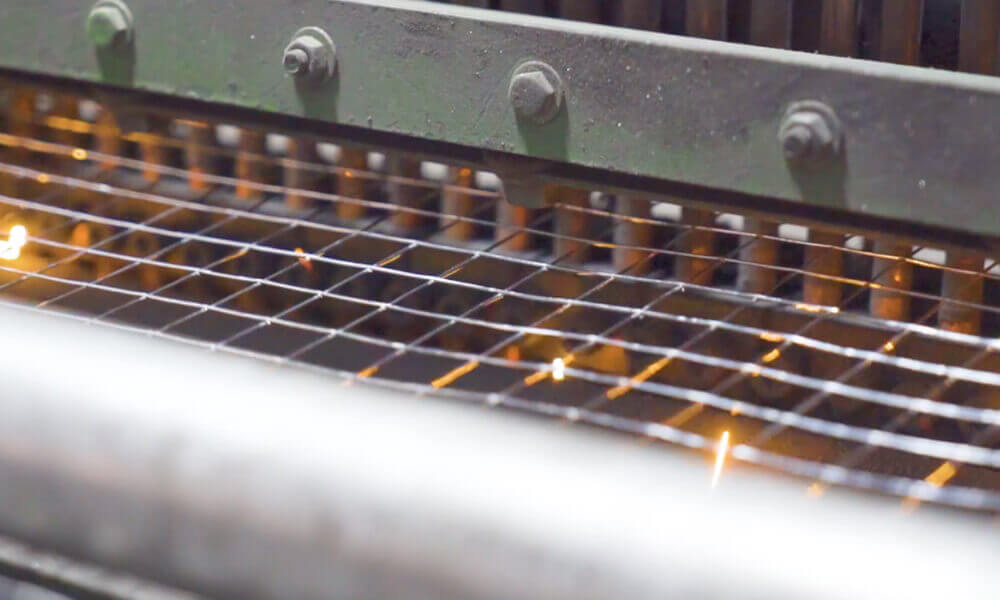

Hot-dip galvanization involves immersing the wire in molten zinc heated to a high temperature for plating. It features fast production speed, a thick but uneven zinc coating, and a relatively dull color. This process consumes a large amount of zinc metal. Importantly, it forms an infiltration layer with the base metal, resulting in excellent corrosion resistance—hot-dip galvanized wire can maintain its performance for several decades in outdoor environments.

Hot-dip galvanized wire is widely used in industries such as chemical equipment manufacturing, petroleum processing, marine exploration, metal structure construction, power transmission, and shipbuilding. In recent years, it has also been extensively applied in the agricultural sector, including pesticide sprinkler systems and greenhouse frameworks, as well as in the construction industry, such as for water and gas transmission pipelines, wire casings, scaffolding, bridges, and highway guardrails.

Cold-Dip Galvanized Wire (Electro-Galvanized Wire)

Cold-dip galvanized wire (electro-galvanized wire) is produced by gradually depositing zinc on the metal surface through unidirectional electric current in an electroplating tank. It has slow production speed, a uniform but thin zinc coating (usually only 3-15 microns), and a bright appearance. However, its corrosion resistance is poor, and it typically begins to rust within a few months.

Compared with electro-galvanization (the process for cold-dip galvanized wire), hot-dip galvanization has lower production costs and exerts less impact on the environment.

We hope this information is helpful to you!