The primary advantage of hot-dip galvanized steel wire is its exceptional resistance to rust and oxidation, coupled with enhanced toughness. This type of wire demonstrates superior performance in environments involving prolonged exposure to rain and sunlight. In contrast, ordinary steel wire is prone to rusting and cracking over time, whereas hot-dip galvanized wire remains intact and corrosion-free even under harsh conditions.

Advantages of Hot-Dip Galvanized Wire:

1.Exceptional Durability:

In suburban settings, hot-dip galvanized coating can provide rust protection for over 30 years. In urban or coastal areas, it maintains effective corrosion resistance for up to 15 years.

2.Excellent Reliability:

The galvanized layer metallurgically bonds with the steel, becoming an integral part of the surface and ensuring long-lasting protection.

3.High Toughness:

The unique metallic structure of the galvanized coating offers robust resistance to mechanical damage during handling and use.

4.Comprehensive Coverage:

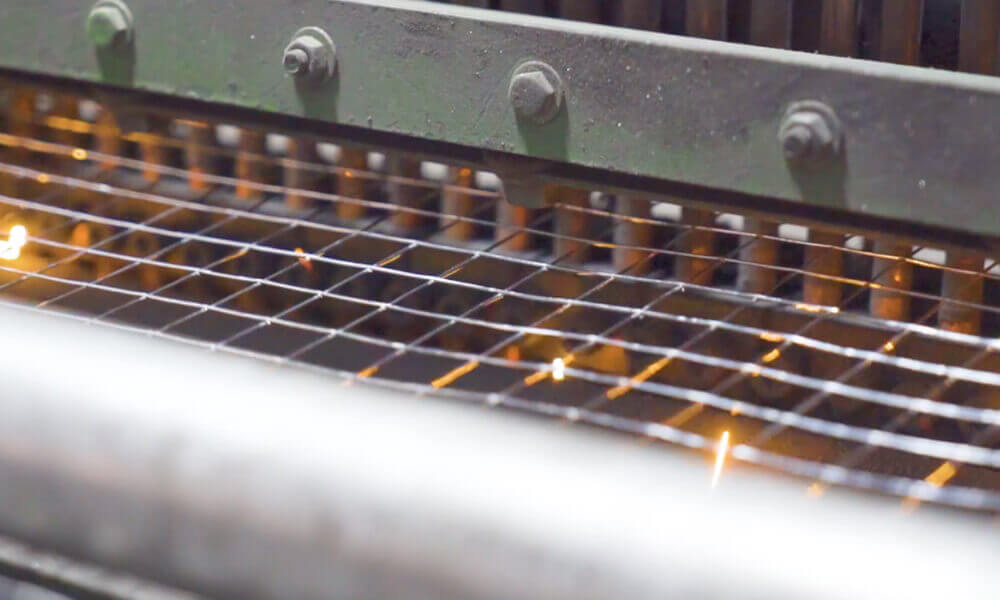

The hot-dip galvanizing process ensures complete coverage, including recesses and sharp edges, providing uniform protection.

5.Time and Labor Efficiency:

Galvanizing is a faster process compared to other coating methods, eliminating the need for additional on-site painting after installation.

Differentiating Hot-Dip and Electro-Galvanized Wire

Apart from hot-dip galvanized steel wire, electro-galvanized (cold-galvanized) wire is also available. However, electro-galvanized wire offers limited corrosion resistance and may begin to rust within months, whereas hot-dip galvanized wire can endure for decades. It is crucial to distinguish between these two types to avoid industrial or safety issues arising from inadequate corrosion protection.

That said, electro-galvanized wire has a lower production cost and remains widely used for specific applications where extreme durability is not required. Hot-dip galvanized wire, manufactured from low-carbon steel, has a darker appearance compared to electro-galvanized wire.

Key Features of Hot-Dip Galvanized Steel Wire:

High Tensile Strength:

The tensile strength of high-grade 270-class low-relaxation prestressed galvanized steel wire can reach 1860 MPa. This is approximately 3.5 times higher than that of Grade II steel bars of the same cross-sectional area, 5–6 times higher than A3 round steel, and 1.1–1.7 times higher than non-high-strength steel wire. As a result, using hot-dip galvanized steel wire in construction can significantly reduce the required amount of steel, decrease concrete volume, and lighten the overall structure.

Low Relaxation Prestress:

Due to the pretension applied during manufacturing, hot-dip galvanized steel wire exhibits low relaxation values, minimal stress loss, and excellent stability under load. It maintains strong elasticity without deformation or fracture, offering performance advantages that traditional steel rebars cannot match.